PCB PROFESSIONAL MANUFACTRRER!

PCB PROFESSIONAL MANUFACTRRER!

To guarantee that the thickness of surface coatings on our PCB boards meets customer specifications, our company has invested in an advanced X-RAY detector. This technology allows us to accurately measure the thickness of critical surface coatings, including gold, nickel, and tin.

By testing the thickness of these coatings, we ensure that each PCB board adheres to the required standards, preventing issues such as insufficient or excessive coating that could affect conductivity, solderability, or long-term reliability.

To meet the high-quality requirements of our customers, particularly regarding solderability, our company has invested in an advanced ion contamination tester. This equipment is essential for ensuring that all PCB boards we ship are clean and free from any foreign matter residues that could compromise solderability.

By identifying and eliminating ion contamination, we prevent potential solderability problems that could arise during assembly. This proactive approach reduces the risk of defects, minimizes rework, and ensures that the final product meets the customer's expectations.

Specializing in the production of characteristic impedance PCB boards, our company excels in manufacturing multi-layer boards that meet various impedance requirements. Customers often specify different impedance values, such as 50 ohm, 80 ohm, and 100 ohm etc, across different conductor areas in their product designs. These requirements are well within our capabilities. With advanced impedance testing equipment, we ensure comprehensive quality control from design through to manufacturing, guaranteeing that our boards meet the exact specifications needed."

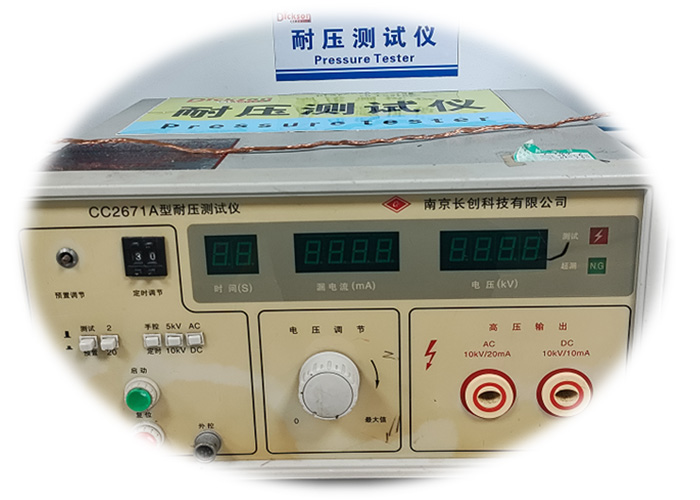

Our company utilizes Hi-Pot testers primarily for power supply PCBs with thick copper plating, which are integral to industrial power supply products used by our customers. To ensure the highest standards of product quality, we have invested in advanced high voltage testing equipment. This allows us to rigorously assess the PCB's ability to withstand specified voltage and current parameters, ensuring that every board we deliver fully meets our customers' stringent requirements."