PCB PROFESSIONAL MANUFACTRRER!

PCB PROFESSIONAL MANUFACTRRER!

IQC (Incoming Quality Control) is crucial to maintaining our product quality. With the increasing demand for environmentally friendly products, many of our customers require that our PCB boards comply with ROHS standards. To prevent the introduction of non-compliant materials into our production process, we have invested in a ROHS detector. This enables us to rigorously test all incoming raw materials, ensuring that our PCB circuit board shipments fully meet ROHS requirements.

IQC plays a critical role in maintaining our product quality. As the demand for environmentally friendly products grows, many of our customers require that our PCB boards comply with ROHS standards. To ensure compliance, we perform ROHS testing on all externally sourced raw materials, including solder masks and laminates. By verifying that these materials meet ROHS standards, we ensure that the PCB boards we produce fully meet our customers' requirements.

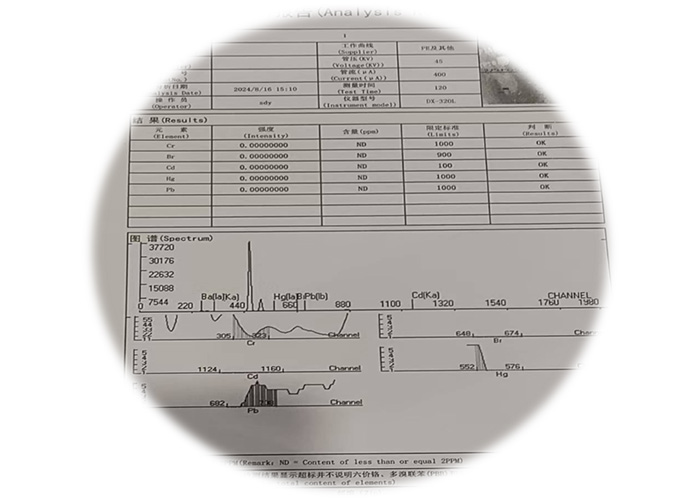

Attached is a test result demonstrating compliance with ROHS standards

The copper foil tensile tester is a specialized piece of equipment used to evaluate the adhesion strength of copper on incoming PCB copper clad laminate materials. By testing these incoming laminates, we ensure the quality of the raw materials and, consequently, the adhesion quality of the copper foil in our finished PCB products. This rigorous testing process helps us meet and exceed our customers' product quality requirements."

"The copper foil tensile tester is a specialized device used to assess the adhesion strength of copper on incoming PCB copper clad laminate materials. We perform pull-strength tests on laminates of various thicknesses (e.g., 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm) and copper thicknesses (e.g., 0.5 oz, 1 oz, 2 oz, 3 oz) to ensure that all raw materials meet our quality standards. This rigorous testing ensures that the copper foil adhesion quality of our finished PCB products complies with our stringent requirements and those of our customers.