PCB PROFESSIONAL MANUFACTRRER!

PCB PROFESSIONAL MANUFACTRRER!

Ensuring the highest standards in packaging quality control is essential to protect products during transit and maintain brand integrity. Our process involves rigorous inspections at every stage of packaging, from material selection to final sealing. We verify that packaging materials meet specified strength and durability requirements and conduct tests for proper sealing, weight distribution, and resistance to environmental factors. Our team is trained to identify and rectify any defects, ensuring that every package meets our strict quality criteria before it reaches the customer.

To further guarantee packaging quality, our company offers three different types of packaging materials: bubble film, PE bags, and aluminum foil. Below are examples of each type of packaging."

customer can choose any style package what they want

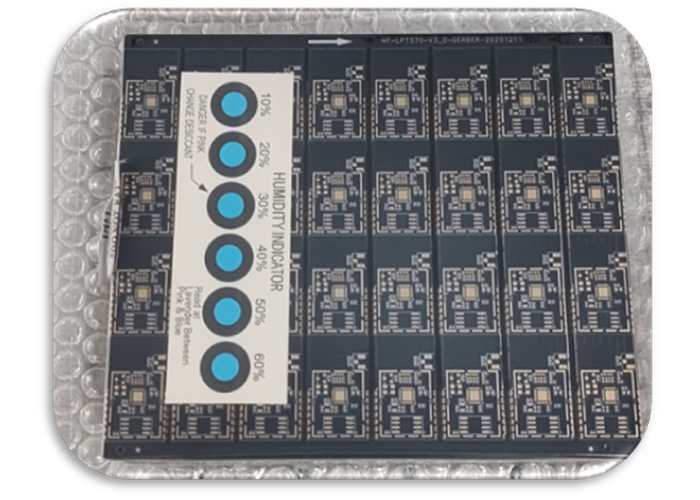

Bubble film packaging is a universal packaging in the circuit board industry. We will put moisture-proof agent in the packaging. Some customers require humidity card in addition . To be honest, this kind of packaging cannot have higher moisture-proof function like PE BAG or aluminum foil bag, so it is meaningless to put humidity card.

Dual-Use Packaging for PCB Boards.In the PCB industry, dual-use packaging offers versatile protection and convenience for handling and shipping circuit boards. This innovative packaging solution is designed to serve both protective and functional purposes, ensuring that PCBs are securely protected during transit while also being easy to handle and store.

Additionally, dual-use packaging is engineered for efficiency, allowing for easy stacking and storage. This reduces the overall footprint and simplifies inventory management. By combining protective qualities with practical handling features, our dual-use packaging ensures that PCB boards arrive in optimal condition, meeting the highest standards of quality and reliability.

But its cost is a little bit high than the bubble film package.

Dual-Use Packaging for PCB Boards.In the PCB industry, dual-use packaging offers versatile protection and convenience for handling and shipping circuit boards. This innovative packaging solution is designed to serve both protective and functional purposes, ensuring that PCBs are securely protected during transit while also being easy to handle and store.

Additionally, dual-use packaging is engineered for efficiency, allowing for easy stacking and storage. This reduces the overall footprint and simplifies inventory management. By combining protective qualities with practical handling features, our dual-use packaging ensures that PCB boards arrive in optimal condition, meeting the highest standards of quality and reliability.

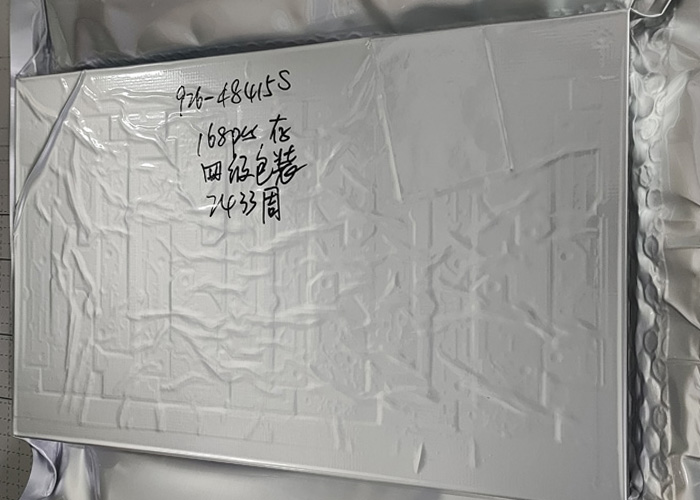

Aluminum foil bags combined with bubble film represent the most costly packaging option among the three available styles. This high cost reflects the superior level of protection they offer, including enhanced moisture resistance and impact cushioning, compared to other packaging methods."